What is an OBD II? OBD II, or On-Board Diagnostics II, is a vehicle system for diagnosing and reporting issues. Standard since 1996, it helps monitor engine performance and emissions. This article will explain how OBD II works, its benefits, and how to use it.

Key Takeaways

- OBD II (On-Board Diagnostics II) is a standardized system introduced in 1996 that provides real-time diagnostics and emissions data for vehicles, democratizing vehicle maintenance by enabling owners to use OBD II scanners to read diagnostic trouble codes (DTCs).

- The OBD II system includes a standardized 16-pin port, typically located under the dashboard, through which users can access diagnostic data and perform maintenance checks using various communication protocols, ensuring consistency across different vehicle brands.

- The system’s evolution from OBD I to OBD II introduced standardized DTCs and real-time data capabilities, significantly improving diagnostic accuracy and efficiency, while future advancements may include enhanced remote diagnostics through telematics and the possible development of OBD3 for continuous vehicle health monitoring.

What is OBD II?

OBD II, which stands for On-Board Diagnostics II, is a standardized system for self-diagnostics and reporting in vehicles. It functions as the vehicle’s built-in self-diagnostic system, providing real-time data on engine performance and emissions. This system became mandatory for vehicle models from 1996 onwards, aimed at complying with federal emissions standards in the United States.

GAIN MORE CONTROL OF YOUR CAR WITH THE CARLY FEATURES

Check the exact pricing of Carly for your car brand!

Fast International Shipping with DHL

14 days adaptor return policy

Excellent customer support

Lifetime warranty in the hardware

SEEN IN

OBD II proved to be powerful in its capacity to provide valuable insights for heavy duty vehicles, as it can:

- Observe engine component performance

- Identify engine failure and emission-related issues

- Provide access to data from the engine control unit (ECU)

- Enable vehicle owners or repair technicians to access the status of various vehicle sub-systems

- Rapidly identify malfunctions within the vehicle, making diagnostics more efficient and accessible.

A prime benefit of OBD II is how it has democratized vehicle diagnostics. Before its standardization, diagnosing vehicle issues often required specialized knowledge and tools. Now, with the OBD II specification, even regular vehicle owners can use an OBD II scanner to read diagnostic trouble codes and understand the nature of the problem. This accessibility has transformed how we approach vehicle maintenance.

Additionally, OBD II systems leverage a digital communication port to deliver real-time data and diagnostic trouble codes. This port, known as the OBD II port, is the gateway through which mechanics and vehicle owners can diagnose and fix issues. The OBD II system’s ability to detect and control engine failures, performance issues, and vehicle emissions makes it an invaluable tool for maintaining vehicle health and ensuring compliance with emissions regulations.

The Evolution of On-Board Diagnostics

On-board diagnostics embarked on their journey in the 1980s, with OBD I’s introduction, which centralized its focus on monitoring emission-related components. These early obd systems provided basic feedback, often through simple illumination or malfunction indicator light, without the detailed data we have today. The regulatory intent behind OBD I was to encourage auto manufacturers to design reliable emission control systems.

As technology advanced, the limitations of OBD I became apparent, leading to the development of OBD II. One of the most significant changes introduced with OBD II was the standardization of diagnostic trouble codes (DTCs), which provided a uniform method of identifying vehicle issues. This standardization made it easier for mechanics and vehicle owners alike to diagnose problems accurately and efficiently. In addition to DTCs, OBD II systems also offered real-time data, greatly enhancing the diagnostic capabilities.

Starting in 1996, all cars and light trucks, including diesel vehicles, sold in the United States were required to have OBD II, marking a noteworthy milestone in vehicle diagnostics. This mandate not only improved the reliability of emission control systems but also made vehicle diagnostics more sophisticated and accessible. The evolution from OBD I to OBD II represents a leap in technology, transforming how we monitor and maintain various vehicle systems.

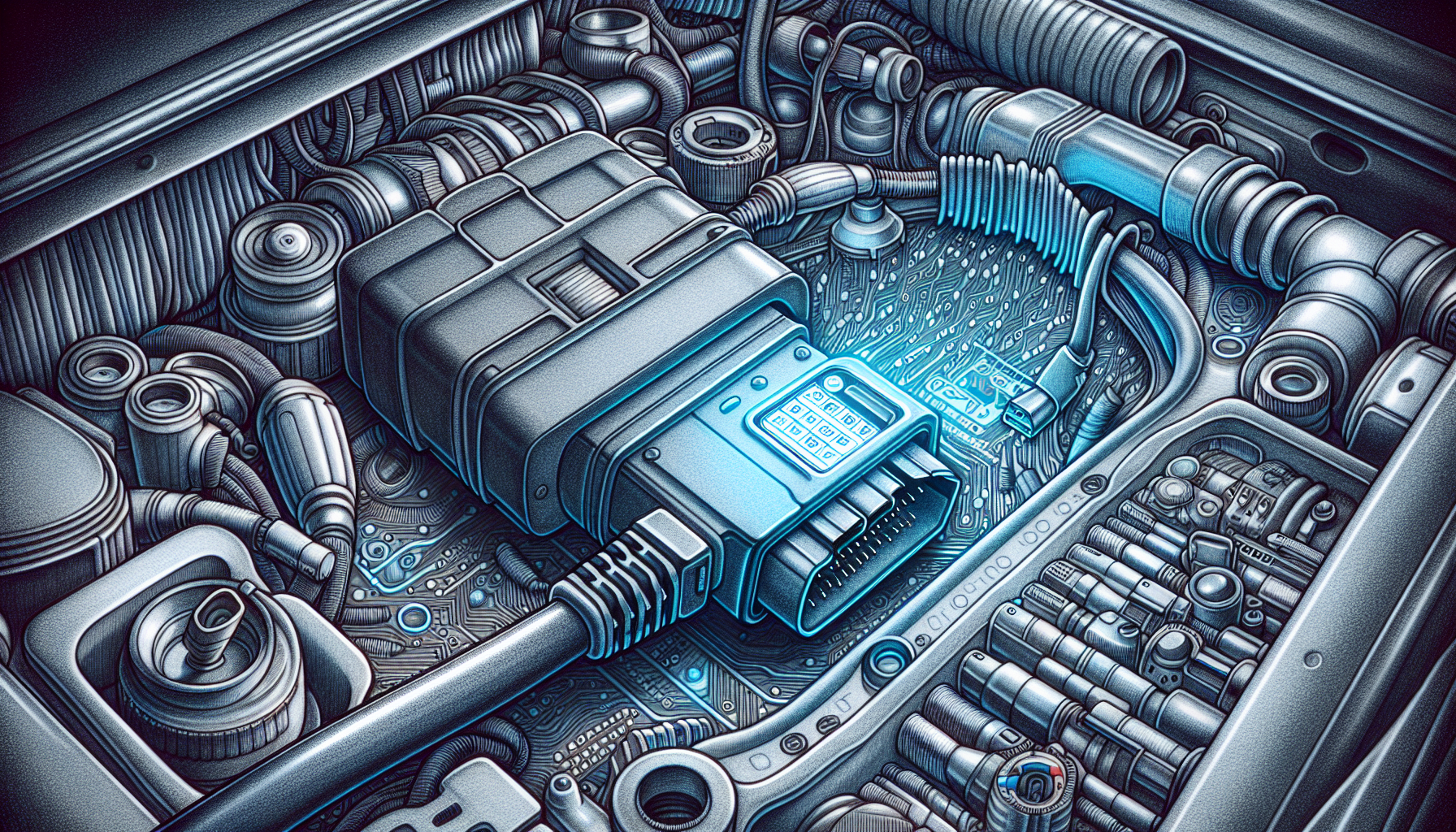

The OBD II Port: Your Gateway to Vehicle Diagnostics

The OBD II port, a standard connection point, facilitates access to a vehicle’s diagnostic data. Typically, this multi-pin (commonly 16-pin) connector is located beneath the dashboard on the driver’s side, within easy reach. Its standardized design means that it can be used across different makes and models of vehicles, providing a universal interface for vehicle diagnostics.

The OBD II port serves as the gateway to the vehicle’s brain, enabling mechanics and vehicle owners to access real-time data streams and diagnostic trouble codes. Through this port, one can read data from multiple sensors, including engine temperature, RPM, and speed. This wealth of information can be used to diagnose and fix issues, ensuring the vehicle runs smoothly. External scanning devices, such as emission testers, can also connect to the vehicle’s ECUs through the OBD II port to perform comprehensive checks.

The SAE J1962 specification defines two types of diagnostic connectors: Type A and Type B. These connectors are used in vehicle diagnostics and maintenance. Type A has a 12V power supply output and uses a 500K baud rate, while Type B has a 24V power supply output and uses a 250K baud rate, with recent support for 500K. Despite these variations, the OBD II connector must be located within 2 feet (0.61 m) of the steering wheel, making it easily accessible for diagnostics. This standardization ensures that vehicle diagnostics can be performed quickly and efficiently, no matter the make or model of the car.

Diagnostic Trouble Codes (DTCs)

Diagnostic Trouble Codes (DTCs) are the heart of the OBD II system, providing specific identification of issues within the vehicle. These alphanumeric codes are generated by the vehicle’s on-board diagnostics whenever a fault is detected, helping pinpoint the exact location and nature of the malfunction. For example, common DTCs include codes like P0442 for a small leak in the evaporative emission control system and P0606 for a malfunction in the powertrain control module.

A DTC typically follows a standardized format:

- The first character is a letter indicating which control system has an issue, such as ‘P’ for powertrain or ‘C’ for chassis.

- The second character is a digit that shows whether the code is standardized (0) or manufacturer-specific (1).

- The third character identifies the vehicle subsystem at fault, such as 1 for the fuel or air metering system.

- The fourth and fifth characters form a two-digit number that pinpoints the specific issue.

This structured format allows for precise diagnostics and efficient repairs, providing essential diagnostic information.

Comprehending DTCs is vital for vehicle upkeep, as they offer in-depth insights into the vehicle’s condition. By using an OBD II scanner to read these codes, car owners can quickly identify problems and take appropriate action. This capability not only simplifies diagnostics but also helps in maintaining the vehicle’s performance and longevity.

Communication Protocols Used in OBD II

OBD II systems employ uniform communication protocols to guarantee consistency and compatibility across various vehicle brands and designs. These protocols enable access to a broad range of standard parameter IDs for data analysis, including vehicle speed, RPM, and throttle position. The OBD-II interface permits five signaling protocols, which make diagnostics simpler and more uniform. This helps in ensuring consistency and ease of use across different diagnostic tools and systems.

The most commonly used protocols include:

- SAE J1850 PWM, predominantly used by Ford

- SAE J1850 VPW, which is common in General Motors vehicles

- ISO 9141-2, primarily utilized by Chrysler and most Asian manufacturers

- ISO 14230-4, also known as KWP2000, commonly used in various European and Asian vehicles

- ISO 15765 (CAN bus) protocol, which has been mandatory in US cars since 2008, and is the most recent and versatile, supporting high-speed communication up to 1 Mbps.

These communication protocols are essential for the effective operation of OBD II systems, allowing for seamless data transfer and diagnostics. By standardizing these protocols, the OBD II system ensures that vehicle diagnostics are consistent and reliable, regardless of the vehicle’s make or model. This consistency is vital for accurate diagnostics and efficient repairs, benefiting both mechanics and vehicle owners alike.

How to Use an OBD II Scanner

The use of an OBD II scanner is a simple process, enabling vehicle owners to detect and resolve issues autonomously. The first step is to locate the OBD II port, which is usually found beneath the dashboard on the driver’s side. Once the port is located, ensure the vehicle’s ignition is off before connecting the scanner to avoid any electrical issues.

After securely connecting the scanner to the port, turn the vehicle’s ignition to the ‘on’ position without starting the engine. This step powers the vehicle’s electrical systems and allows the scanner to initialize and connect to the vehicle’s onboard diagnostics system. Select the ‘Read Codes’ option on the scanner to begin diagnosing any logged diagnostic trouble codes (DTCs).

The scanner will display any detected DTCs, providing insights into the vehicle’s issues. Once the codes are read, you can look up their meanings in the scanner’s manual or online to understand the specific problems. If needed, you can also clear the codes using the scanner, although this action resets the vehicle’s system but does not fix the underlying issue.

Using an OBD II scan tool is a practical skill that can save time and money by allowing you to handle minor diagnostics and repairs on your own.

Advantages of OBD II Systems

OBD II systems bring numerous benefits that boost vehicle upkeep and performance. One of the primary benefits is the provision of real-time information on vehicle performance, which aids in quick and accurate diagnostics. This capability allows vehicle owners to detect and address issues before they become severe, reducing maintenance costs and preventing major repairs.

The evolution of OBD II technology has shifted vehicle maintenance from reactive to proactive. By identifying issues early, OBD II systems enable preventive maintenance, which can significantly reduce the cost and time associated with major vehicle repairs. For mechanics, OBD II systems streamline diagnostics and repair processes through detailed trouble codes, making their job easier and more efficient.

Enhanced emissions control capabilities are another significant advantage of OBD II systems. By monitoring and optimizing engine performance, these systems help reduce the environmental impact of vehicles and improve fuel efficiency. Overall, OBD II systems contribute to better vehicle health, lower maintenance costs, and a cleaner environment.

OBD II and Emission Standards

OBD II systems perform a key function in confirming compliance with emission standards established by regulatory authorities such as the Environmental Protection Agency (EPA) and the California Air Resources Board (CARB). These systems monitor virtually every component that can affect emission performance in vehicles, ensuring that emissions remain low throughout the vehicle’s life.

The EPA requires all 1996 and newer passenger cars and trucks to meet OBD II requirements, making it a critical component of federal emission standards based on the Clean Air Act. In California, OBD II checks are part of the state’s Smog Check program, where technicians perform an OBD II check during inspections to detect faults affecting emissions. Improved compliance with emissions regulations can lead to reduced fines and penalties for businesses, making it beneficial for both vehicle owners and manufacturers.

The CARB emission warranty requires manufacturers to fix OBD II detected problems for vehicles sold within the last three years and with less than 50,000 miles, ensuring that vehicles remain compliant with emission standards. This regulatory framework underscores the importance of OBD II systems in maintaining vehicle health and reducing environmental impact.

OBD II Data Logging

OBD II data logging entails the collection and analysis of real-time vehicle performance data, proving invaluable for troubleshooting, research, and upkeep. Advanced OBD II scanners can stream live data, allowing real-time observation of vehicle performance parameters such as speed, RPM, and engine temperature. This real-time data can be used to monitor and optimize driving behavior and vehicle performance.

One of the key features of advanced scanners is the ability to capture freeze frame data. This data snapshot records the vehicle’s condition at the moment a trouble code is triggered, providing crucial information for diagnosing intermittent issues. By analyzing this data, mechanics and vehicle owners can pinpoint the exact circumstances leading to a fault, making it easier to resolve complex problems.

For fleet management, OBD II data logging is particularly beneficial. It can aid in driver behavior research, fuel cost reduction, and predictive maintenance. By integrating OBD II data loggers with GPS/IMU data, fleet managers can track position, speed, trip distance, and more, leading to more efficient and effective fleet operations.

OBD II data logging thus extends the utility of OBD systems beyond simple diagnostics, offering insights that can enhance vehicle performance and operational efficiency.

Future of OBD II Technology

The future trajectory of OBD II technology signals thrilling advancements that could drastically transform vehicle diagnostics and maintenance. One potential development is the integration of OBD II with telematics devices, which would enhance remote diagnostics capabilities. This integration would allow vehicle data to be transmitted to remote servers, enabling real-time monitoring and diagnostics from anywhere in the world.

Another potential advancement is the development of OBD3, which involves adding telematics to all cars. This evolution could significantly change how we approach vehicle diagnostics, offering:

- Continuous monitoring of vehicle health and performance

- Detection and addressing of issues before they manifest as noticeable problems

- More proactive and efficient vehicle maintenance

The future of OBD II technology holds promising developments that could not only improve vehicle diagnostics but also enhance overall vehicle management. As these technologies evolve, they will likely bring about more sophisticated tools and methods for maintaining vehicle health, reducing environmental impact, and improving fuel efficiency. Embracing these advancements will be crucial for both vehicle owners and the automotive industry as a whole.

Summary

Understanding the OBD II system is essential for modern car owners who want to take control of their vehicle maintenance and diagnostics. This guide has provided a comprehensive overview of what OBD II is, its evolution, and how it functions. We’ve explored the practical aspects of using an OBD II scanner, the significance of diagnostic trouble codes, and the communication protocols that make vehicle diagnostics consistent and reliable.

The advantages of OBD II systems are numerous, from real-time monitoring and proactive maintenance to enhanced emissions control and improved fuel efficiency. These systems not only help in maintaining vehicle health but also ensure compliance with stringent emission standards set by regulatory bodies like the EPA and CARB.

As we look to the future, the integration of OBD II with telematics devices and the potential development of OBD3 promise to revolutionize vehicle diagnostics and maintenance. Embracing these advancements will be crucial for staying ahead in vehicle management and ensuring our vehicles remain efficient, reliable, and environmentally friendly. Take control of your vehicle’s health today by understanding and utilizing the power of OBD II technology.

Frequently Asked Questions

What is the main purpose of OBD II?

The main purpose of OBD II is to monitor engine performance and emissions by providing real-time data and diagnostic trouble codes to identify and resolve vehicle issues effectively.

Where is the OBD II port located in most vehicles?

In most vehicles, the OBD II port is located beneath the dashboard on the driver’s side, within 2 feet of the steering wheel.

How do I use an OBD II scanner to read trouble codes?

To read trouble codes using an OBD II scanner, locate the OBD II port in your vehicle, connect the scanner, turn the ignition to the ‘on’ position, and select ‘Read Codes’ on the scanner.

What are Diagnostic Trouble Codes (DTCs)?

Diagnostic Trouble Codes (DTCs) are alphanumeric codes used by a vehicle’s OBD system to pinpoint specific issues and their location.

How does OBD II help with emission standards?

OBD II helps with emission standards by monitoring vehicle components to ensure compliance with regulations set by authorities like the EPA and CARB. This helps in reducing harmful emissions released by vehicles on the road.